Understanding Comprehensive Truck Diagnostic and Repair Services

For fleet operators and truck owners, ensuring efficiency and reliability on the road hinges significantly on the effectiveness of truck diagnostic and repair services. Modern trucks are complex machines equipped with advanced technology that monitors various systems. Comprehensive truck diagnostic and repair services not only aim to identify and rectify existing issues but also prevent potential future breakdowns. In this guide, we will delve into the intricacies of these services, highlighting their importance and benefits, as well as detailing the best practices for maintaining your fleet’s optimal performance. For in-depth solutions, check out Comprehensive truck diagnostic and repair services.

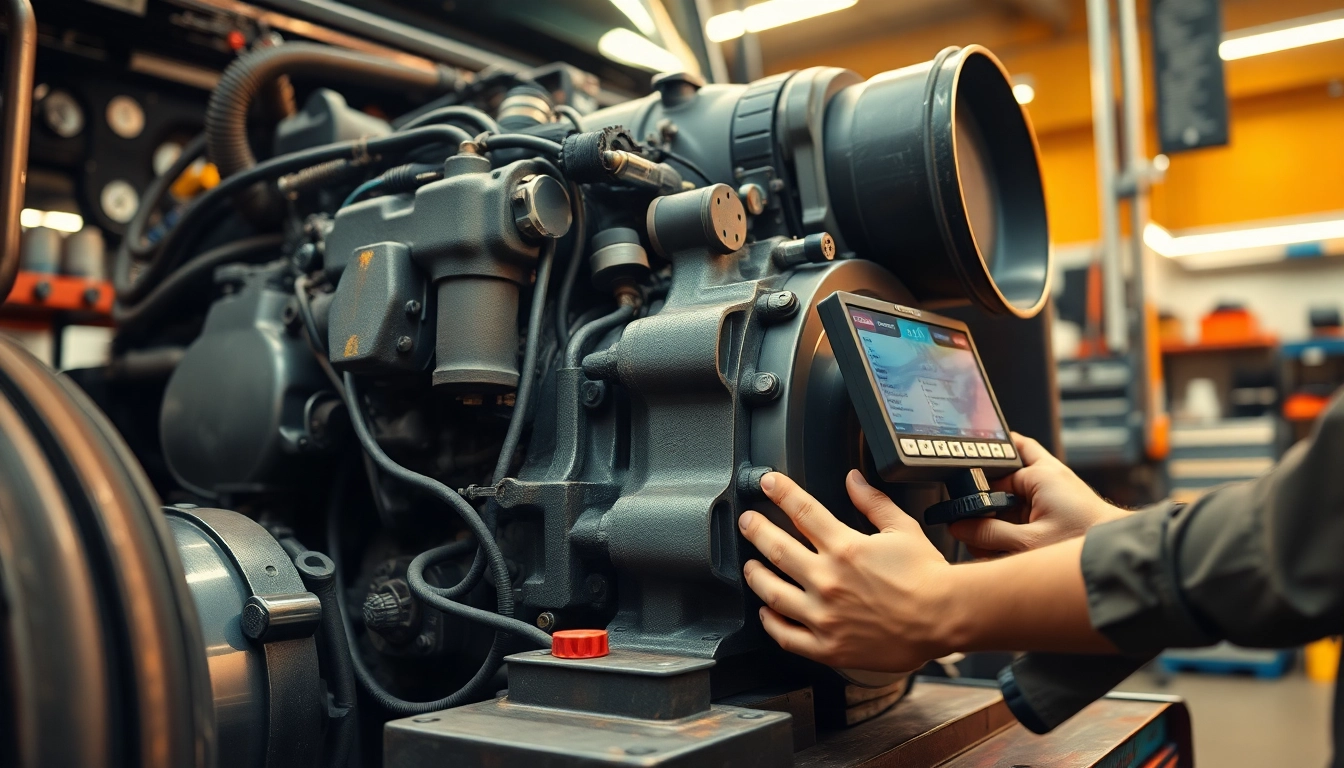

What Are Truck Diagnostic Services?

Truck diagnostic services entail the use of specialized equipment and software to analyze a truck’s systems, identifying any malfunctions or inefficiencies. These services typically cover various components, including:

- Engine performance diagnostics

- Transmission assessments

- Electrical system evaluations

- Brake system tests

- Emission system checks

Utilizing advanced diagnostic tools, automotive technicians can conduct a comprehensive analysis of a truck’s performance metrics. This proactive approach helps in timely identification of problems, enabling fleet managers to address issues before they escalate into costly repairs or complete breakdowns.

Importance of Timely Repairs for Trucks

Timely repairs are vital for any vehicle’s performance, but for trucks, the stakes are even higher. Delays in addressing issues can lead to:

- Increased Downtime: Downtime represents lost revenue—every moment a truck is out of service is money not earned. Timely repairs keep trucks on the road.

- Costly Repairs: Ignoring minor issues often leads to major repairs. For example, a small oil leak left unattended may result in engine failure.

- Safety Hazards: Trucks must be safe for driver and public safety. Faulty brakes or electrical systems pose severe risks and can lead to accidents.

- Compliance Issues: Many regions enforce stringent regulations regarding truck emissions and safety. Non-compliance can lead to fines and legal repercussions.

Overview of Common Diagnostic Tools Used

Modern truck diagnostic services leverage a wide range of tools and technologies to assess vehicle condition effectively:

- OBD-II Scanners: On-Board Diagnostics II (OBD-II) scanners connect to the vehicle’s diagnostics port, retrieving fault codes that indicate specific problems.

- Computerized Diagnostic Systems: Advanced software systems can provide insights into engine performance, transmission issues, and other critical components.

- Vibration Analyzers: These tools help in diagnosing mechanical issues such as imbalanced wheels or failing bearings.

- Pressure Test Equipment: Used to evaluate the integrity of various systems, ensuring they operate within standard pressure ranges.

Key Components of Truck Diagnostics

Engine Diagnostics: Pain Points and Solutions

Engine diagnostics are among the most critical services provided in truck maintenance. Common engine problems include:

- Fuel Injection Issues: Problems with fuel injectors can lead to poor fuel economy and increased emissions. Regular visual inspection and electronic testing can provide solutions like cleaning or replacing injectors.

- Cooling System Failures: Overheating can occur if the cooling system fails. Diagnostic tests can uncover leaks or radiator blockages, allowing for timely repairs.

- Exhaust Emission Problems: Failing emission tests can result from various engine inefficiencies. Comprehensive diagnostics help identify root causes, like faulty sensors or clogged catalytic converters.

Electrical System Monitoring and Repairs

The electrical system in trucks is crucial for powering everything from the starter to the headlights. Common electrical problems include:

- Battery Issues: A bad battery can lead to starting difficulties. Regular battery health checks can prevent unexpected failures.

- Wiring Problems: Corrosion or damage to cables can result in electrical shorts or failures. Diagnostic services can pinpoint these issues for prompt resolution.

- Sensor Malfunctions: Sensors for temperature, pressure, and speed must function correctly for optimal performance. Diagnostic scans can detect failures that affect vehicle operation.

Transmission and Brake System Diagnostics

Transmission and brake systems are vital for safe and efficient operation. Common concerns include:

- Transmission Slipping: This can indicate low fluid levels or internal damage. Regular inspections can help identify potential issues before they require costly repairs.

- Brake Wear: Expired brake pads and warped rotors can lead to catastrophic failures. Scheduled maintenance should include brake system checks to ensure safety.

- Fluid Leaks: Both transmission and brake systems depend on specific fluids. Diagnostics can help locate and remedy leaks punctually.

Best Practices in Truck Maintenance and Repairs

Routine Maintenance Checklist for Fleets

A robust maintenance schedule helps maximize fleet efficiency. Key elements of an effective routine maintenance checklist include:

- Engine oil and filter changes at specified intervals.

- Regular inspections of the brake system.

- Tire pressure checks and tread assessments.

- Battery and electrical system diagnostics.

- Fuel system cleaning and inspections.

Implementing a detailed checklist will ensure that maintenance is thorough and played out consistently.

How to Schedule Your Diagnostic Services Effectively

Effective scheduling of diagnostic services is crucial in minimizing downtime:

- Develop a calendar for regular maintenance checks based on vehicle usage and manufacturer recommendations.

- Set reminders for key service dates, ensuring timely appointments.

- Utilize telematics systems to track vehicle health and performance metrics, allowing for predictive maintenance.

- Plan for peak operational periods to avoid scheduling diagnostics during heavy usage times.

Choosing the Right Repair Facility

Selecting a repair facility for truck diagnostics and repairs is crucial. Important factors to consider include:

- Certifications: Look for facilities with certified technicians who have expertise in heavy-duty trucks.

- Technology and Tools: Ensure the shop utilizes modern diagnostic tools and technology to accurately assess issues.

- Reputation: Read reviews and testimonials to gauge reliability and customer satisfaction.

- Location and Availability: Proximity and flexible operating hours can enhance convenience and minimize downtime.

Cost Considerations for Comprehensive Repair Services

Understanding the Pricing Structure of Truck Repairs

Understanding the cost of truck repairs can help managers budget effectively. Key considerations include:

- Labor Costs: Rates can vary based on the facility’s location and technician expertise. Keep track of labor hours to manage costs.

- Parts and Materials: Prices for replacement parts can fluctuate. Knowing which components typically require replacement can aid budgeting.

- Service Packages: Many facilities offer service packages that can provide cost savings for regular maintenance needs.

Insurance and Warranties: What You Need to Know

Understanding insurance coverage and warranties can prevent unexpected expenses. Important aspects include:

- Verify coverage for diagnostic services under existing insurance policies.

- Check warranty details on parts to ensure future repairs are covered.

- Discuss service agreements with repair facilities since they may provide additional coverage options.

Maximizing ROI on Truck Maintenance

Investing in maintenance and diagnostic services is essential for maximizing the return on investment (ROI) for fleets. To enhance ROI:

- Use telematics data for predictive maintenance scheduling, preventing unscheduled downtime.

- Track individual vehicle performance metrics to identify potential issues before they escalate.

- Regularly review and analyze maintenance expenses to identify opportunities for cost savings.

Future Trends in Truck Diagnostics and Repair Services

The Role of Technology in Diagnostics

Technology continues to shape truck diagnostics and repair industries. Emerging trends include:

- Telematics Integration: Telematics track vehicle performance and health, enabling real-time diagnostics and maintenance planning.

- Artificial Intelligence: AI systems can analyze performance data, making predictive maintenance more reliable and efficient.

- Mobile Apps: Apps enable fleet managers to monitor diagnostics and schedule repairs directly from their devices.

Emerging Diagnostic Tools and Techniques

Innovation in diagnostic tools is enhancing the accuracy and efficiency of truck maintenance:

- Advanced Scanning Tools: New scanning tools leverage AI to quickly assess and diagnose issues.

- Remote Diagnostics: Wireless diagnostics allow technicians to assess vehicles without physically being present.

- 3D Printing for Parts: The ability to print replacement parts on-demand can reduce downtime for repairs.

Sustainability in Truck Repair Practices

As industries pivot towards sustainability, truck repair services are embracing eco-friendly practices including:

- Utilizing biodegradable and eco-friendly lubricants and cleaners.

- Recycling old parts and materials whenever possible.

- Implementing waste management practices to minimize environment impact.

In conclusion, comprehensive truck diagnostic and repair services are integral to the efficient functioning of vehicles in any fleet. By understanding and implementing best practices in maintenance, leveraging cutting-edge technology, and staying informed about industry trends, fleet operators can enhance their fleet’s performance, reduce costs, and ensure safety on the road.