Introduction to Chef Base Repair

In the bustling world of commercial kitchens, efficiency and functionality are paramount. One of the unsung heroes of kitchen appliances is the chef base, a specialized refrigeration unit that not only stores ingredients but also provides a convenient workspace for culinary creations. However, like any essential equipment, chef bases require regular attention and maintenance to function optimally. This article serves as a comprehensive guide to chef base repair, exploring common issues, preventive measures, and essential repair strategies that can enhance longevity and efficiency.

What is a Chef Base?

A chef base is a type of refrigeration unit designed for commercial kitchens, offering both cold storage and a workspace for food preparation. Typically, chef bases come with stainless steel tops that can withstand regular kitchen use, while below, they feature multiple refrigerated drawers or compartments. This design maximizes space, making it easier for cooks to access ingredients while preparing meals. They are particularly popular in operations like restaurants, catering businesses, and other food service establishments requiring quick access to fresh produce, meats, and other perishables.

Common Issues Faced

Despite their sturdy design, chef bases are not immune to problems. Common issues can include:

- Temperature fluctuations: Often caused by compressor failures or issues with the thermostat.

- Condenser coil blockages: Dirt and grease can accumulate, impeding airflow and cooling efficiency.

- Leakage: Refrigerant leaks can lead to inadequate cooling, and they may also indicate more severe underlying problems.

- Electrical malfunctions: These can arise from faulty wiring or malfunctioning components.

Importance of Regular Maintenance

Regular maintenance of your chef base is crucial. It not only prolongs the lifespan of the unit but also ensures that food safety standards are met. Well-maintained equipment can operate more efficiently, reducing energy costs and minimizing the risk of costly breakdowns. Scheduling routine checks can help spot and address potential issues before they develop into major repairs.

Identifying Problems in Your Chef Base

Signs Your Chef Base Needs Repair

Identifying problems early can save both time and money. Here are some warning signs that indicate your chef base may need repair:

- Unusual noises: Sounds like clicking, buzzing, or grinding could signify mechanical issues.

- Warm spots: If certain areas of the unit are warmer than others, it may indicate cooling inefficiency.

- Frost build-up: Excess frost can indicate a problem with the defrost system or improper sealing of the door.

- Condensation: Excess moisture around the unit suggests a problem with seals or insulation.

Diagnostic Tools and Techniques

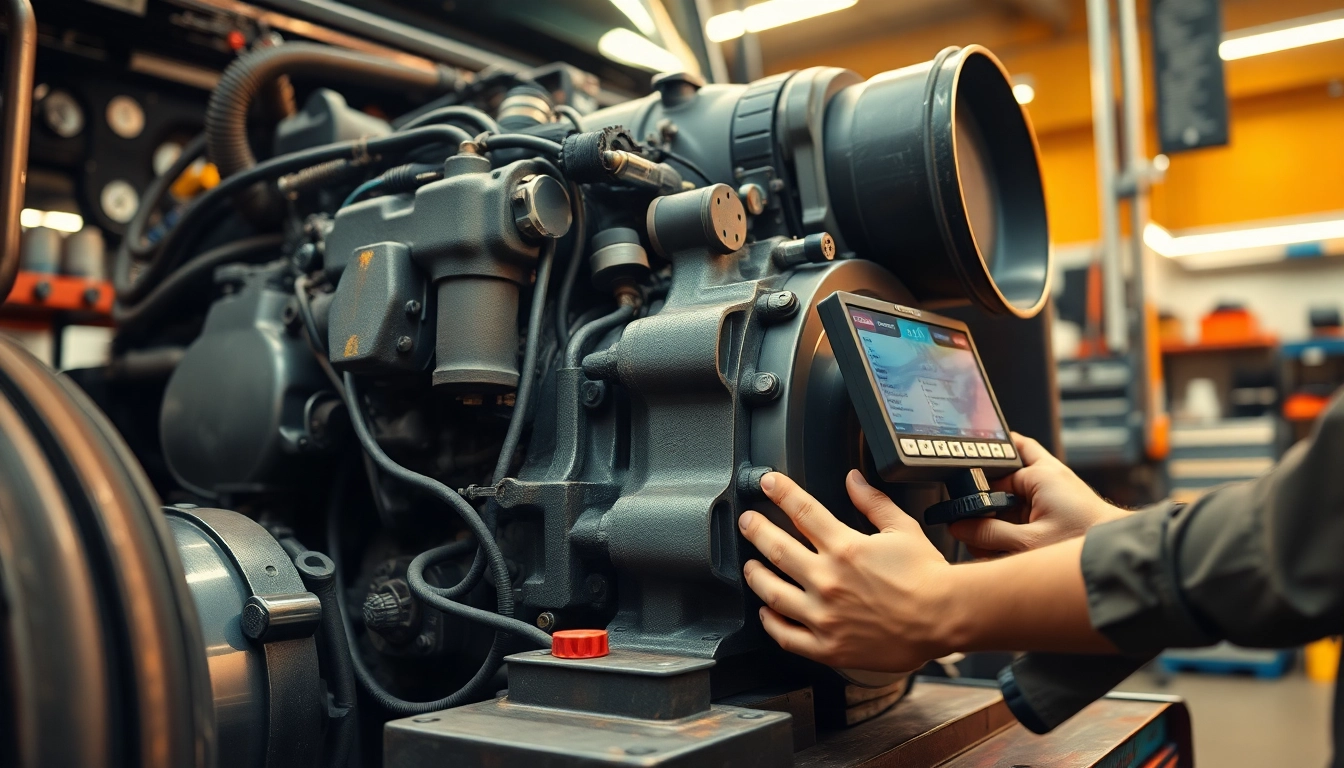

Having the right tools can greatly aid in diagnosing issues in your chef base. Here are some diagnostic methods:

- Thermometers: To check the internal temperature of storage compartments and ensure they are in the desired range.

- Multimeter: This tool can test electrical components to verify that they are operating correctly.

- Pressure gauges: These can help diagnose issues within the refrigerant system, checking for leaks or low refrigerant levels.

Professional vs. DIY Repairs

When it comes to repairs, you might wonder whether to tackle them yourself or hire a professional. If the issue pertains to electrical components or complex refrigeration systems, hiring a licensed technician is often the best route. However, if issues are more straightforward, such as cleaning the condenser coils or replacing faulty seals, these tasks can often be completed by motivated kitchen staff with a bit of guidance.

Essential Repairs for Chef Bases

Replacing Components: A Step-by-Step Guide

When it comes time for repairs, knowing how to replace some of the chef base’s key components can save time and resources. Here’s a breakdown:

- Gather Necessary Tools: Ensure you have screwdrivers, wrenches, and any specific tools required for your chef base model.

- Disconnect Power: Always unplug the unit before beginning any repair work to avoid electrical hazards.

- Remove the affected component: Take off panels carefully to access parts like the compressor, condenser, or temperature control system.

- Install the new part: Follow manufacturer guidelines to correctly integrate the new component.

- Test the unit: Reconnect power and monitor the performance for a while to ensure the repair was successful.

Common Parts That Often Need Replacement

There are several components that tend to wear out over time, necessitating replacement, including:

- Thermostats: To ensure proper temperature control.

- Compressors: To maintain efficient cooling.

- Fan motors: For proper airflow and cooling performance.

- Door seals: To prevent cold air leaks and maintain internal temperatures.

Tools Required for Chef Base Repair

Having the right tools is essential for effective repairs. Common tools include:

- Screwdrivers (flat-head and Phillips)

- Wrenches

- Allen keys

- Thermometers

- Multimeters

Preventive Measures for Chef Base Longevity

Regular Maintenance Routines

Developing a regular maintenance routine will help extend the life of your chef base. Key tasks include:

- Daily cleaning: Wipe down surfaces to prevent grease accumulation.

- Weekly checks: Inspect gaskets and seals for wear with regularity to maintain efficiency.

- Monthly deep clean: Schedule a comprehensive clean that includes condenser coils and internal components.

Best Practices for Cleaning and Care

Proper cleaning and care practices can prevent common issues. Always adhere to these principles:

- Use non-corrosive, mild cleaning agents to scrub surfaces.

- Avoid abrasive materials that can scratch stainless steel surfaces.

- Ensure all parts are dry before reassembling components.

Temperature Monitoring Techniques

Monitoring temperature consistently is vital for food safety. Some effective techniques include:

- Regularly check temperature settings against a calibrated thermometer.

- Install temperature alarms to alert staff of any fluctuations.

- Log temperatures daily to detect patterns that may indicate impending issues.

When to Call a Professional for Chef Base Repair

Understanding When DIY Is Insufficient

While some repairs can be handled in-house, recognizing when to seek professional help is critical. If you encounter issues beyond basic maintenance—such as electrical faults or complex mechanical failures—it’s prudent to consult an expert. Professional technicians possess the expertise and tools necessary for comprehensive diagnostics and repairs.

Finding a Qualified Repair Technician

When searching for a qualified repair technician, consider the following:

- Certifications: Look for technicians with certification in commercial refrigeration.

- Experience: Seek specialists with a track record of working on chef bases specifically.

- References and Reviews: Check reviews and ask for references from previous clients.

Cost Considerations for Professional Repair Services

The cost of hiring a professional for chef base repair can vary widely based on the problem’s complexity, parts needed, and labor rates in your area. On average, simple repairs may range from $100 to $300, while more extensive repairs could exceed $1,000. Understanding these costs can help in budgeting for potential repairs and maintenance needs.

Conclusion

In conclusion, maintaining and repairing your chef base is not merely about ensuring a single unit functions well. It is about sustaining the entire food operation’s efficiency, safety, and longevity. By understanding common issues, implementing preventive maintenance routines, and knowing when to call in professionals, you can ensure that your chef base remains a reliable and integral part of your kitchen for years to come.